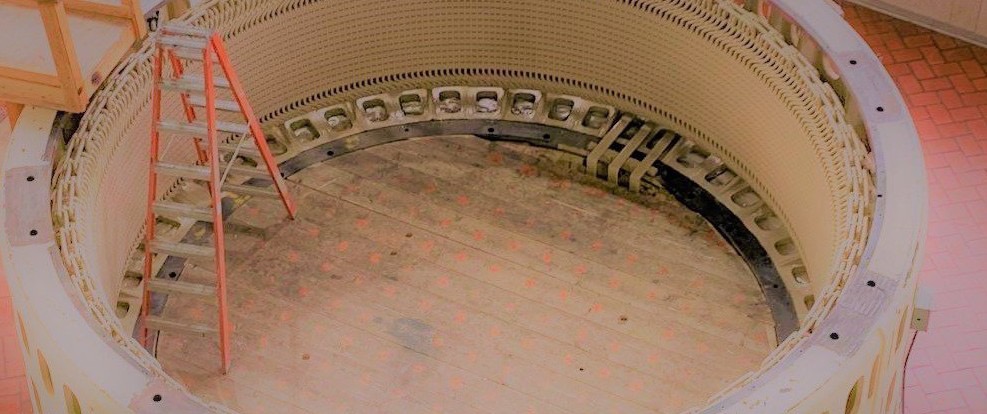

Case Study: Increasing Hydrogenerator Output and Efficiency

AT A GLANCEChallenges 50% increase in output capacity with fixed slot size Expectation for a very long service life. Benefits Greater profitability Used existing generator frame Reduced maintenance requirements Extended asset life It is a pleasure to work with industry experts such as Sidewinders LLC, who offer exceptional levels of quality with a focus on […]

Read moreMotor Rewinds

Sidewinders is excited to announce that our brand-new SAMATIC 2780-EXT is installed, plugged in, and busy rewinding a variety of AC and DC motors! The SAMATIC automatic coil winder can wind any motor, armature, or generator that incorporates mush (or random) winding—both stators and rotors.

Read moreEASA Accreditation

Good for Us and Good for Our Customers Sidewinders is proud of our recent accreditation by EASA (the Electrical Apparatus Service Association). According to Linda Raynes, the President and CEO of EASA, “The intent of this groundbreaking accreditation program is to evaluate service centers for evidence of compliance to assure that they are using prescribed good […]

Read moreGENERATOR ROTOR TESTING

Before we talk about generator rotor testing, let’s make sure we are all on the same page in terms of understanding what a rotor does. First, let’s start with a quick discussion of terminology. Some OEMs such as GE refer to the rotating portion of the generator as the field. Others, such as Siemens refer […]

Read moreFREQUENCY-RESPONSE ANALYSIS (AKA: BUMP TESTING)

Just as every bell has a unique tone when struck by a hammer, so do all generator winding components. Every structure, in fact has its own characteristic modes of mechanical response when deformed after being struck. While not very musical in nature, the response waveform gives the trained Technician valuable information on the integrity of […]

Read more